HITACHI OEM Sprocket EX200 Excacator Spare Parts EX100 EX300

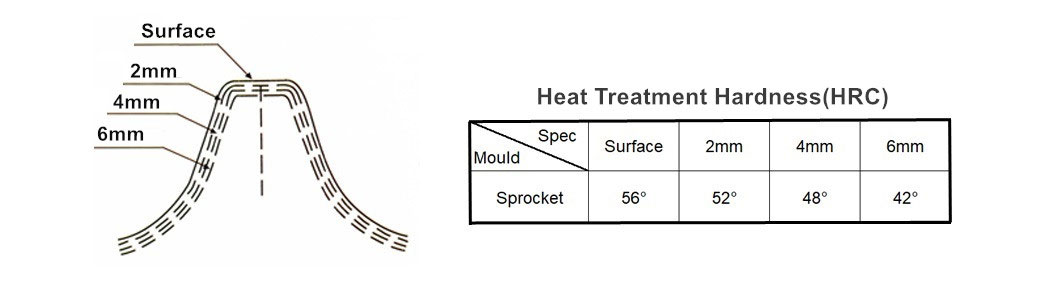

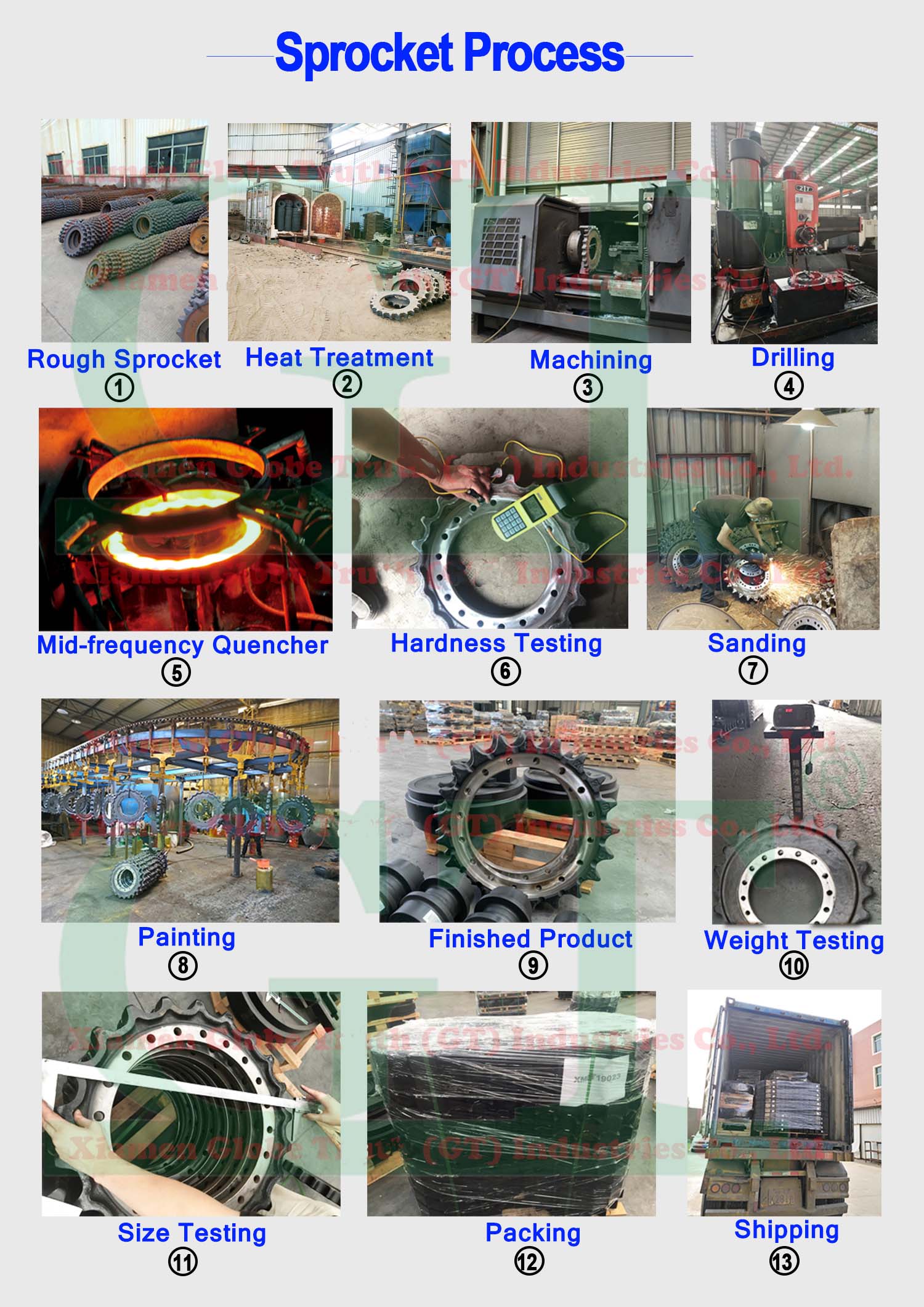

- Through professional quench-tempering processes to guarantee excellent mechanical properties,high strength and superior wear resistance to bending and breakage.

- Produced in advance machining center and vertical CNC turning machine for precision requirements.

- Surface hardness HRC 42-56 for reduced wear and longer life,adding value to your products further to your business by maximizing durability of your products.

- 100% quality assurance, develop and manufacture follow or even exceed original ones.

Sprocket Manufacturing Processes

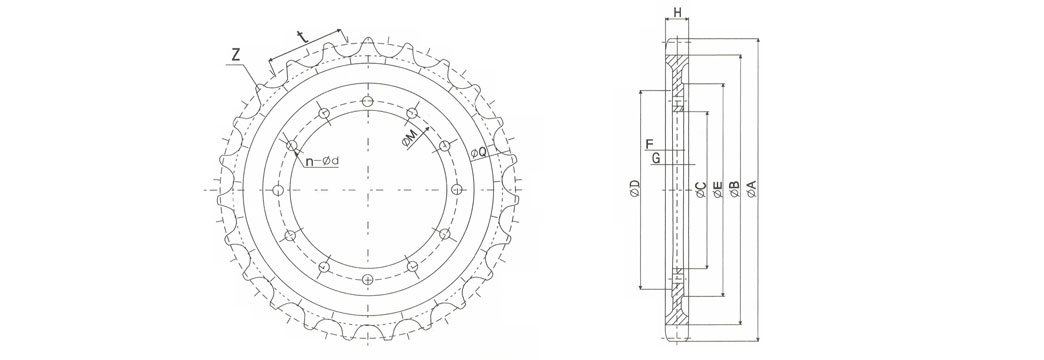

Main Dimensions

| Brand | Model | Main Dimensions of Installation | |||||

| A | Z | C | H | N | D | ||

| HITACHI | EX60-2/3 | 532 | 21 | 330 | 48 | 12 | 17.5 |

| EX100 | 592 | 21 | 356 | 64 | 16 | 18 | |

| EX200-3/5 | 656 | 21 | 420 | 74 | 16 | 21.5 | |

| EX220-2 | 656 | 21 | 432 | 71 | 16 | 22 | |

| EX300-2/3 | 701 | 21 | 465 | 72 | 20 | 22 | |

EC140BL sprocket

Segmented Sprockets

sprocket